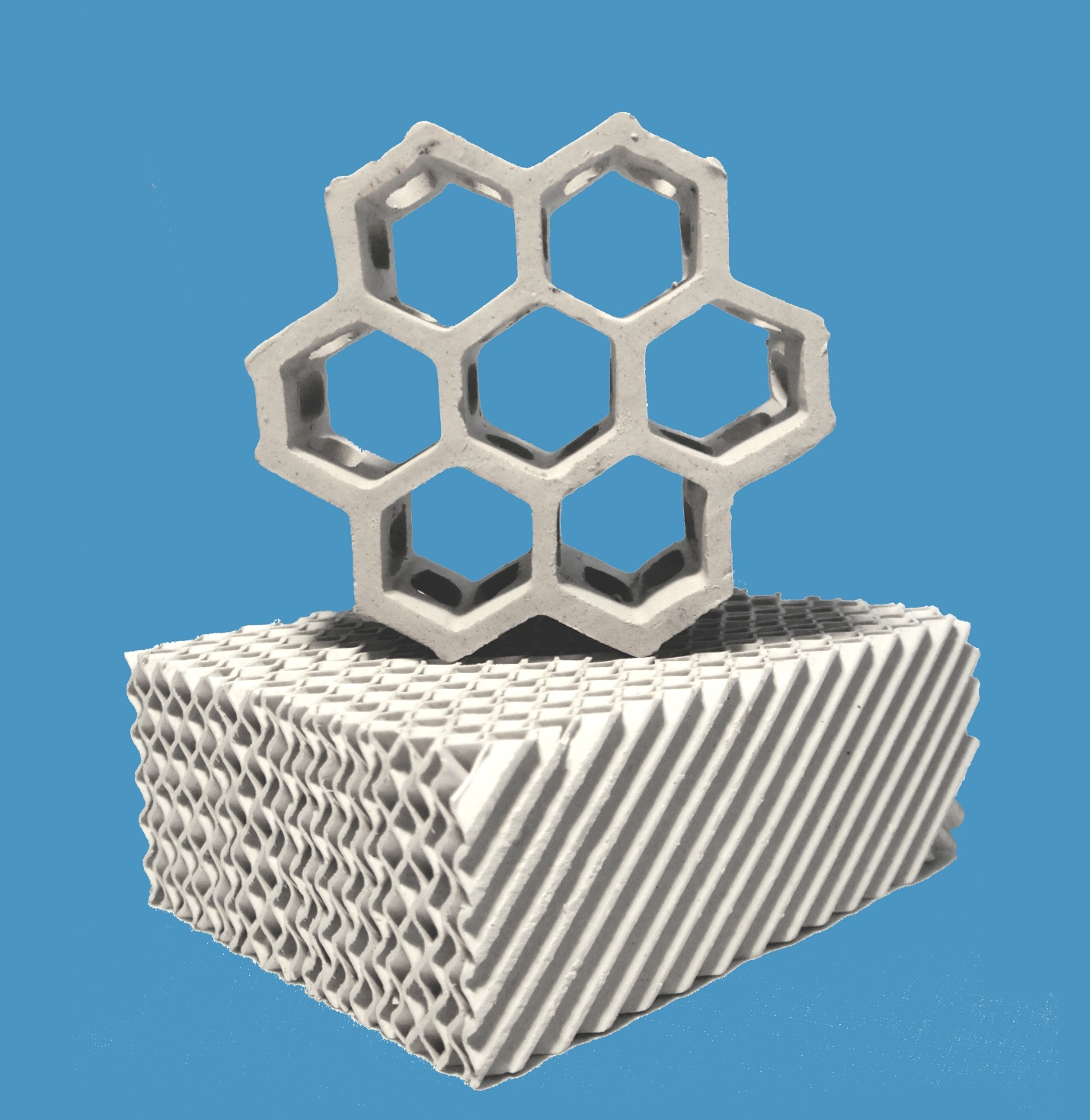

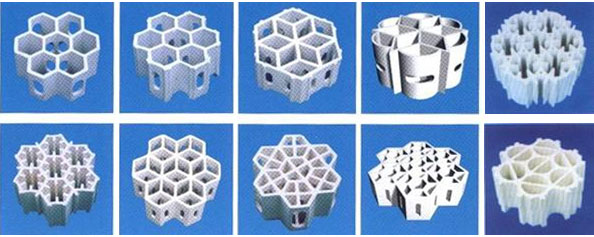

Ceramic Structured Packing

Applications

Widely used as chemical packing in various industries, such as petroleum, coal and coke, power generation and synthetic ammonia industry. Ceramic structured packing is specially designed for use in desulfurization tower, naphthalene removal tower, ammonia scrubber and absorption tower, etc..

Features

- Large surface area and high separation efficiency

- Low pressure drop and low energy consumption

- Strong corrosion resistance

- High thermal shock resistance

- Long service life, easy to install and clean

- High capacity and small liquid holdup

|

Item |

Specific Surface

(m2/m3) |

Bulk Density

(kg/ m3) |

Void Ratio

(%) |

Pressure Drop

(mm Hg/m) |

Number of Theoretical Plate

(m-1) |

Hydraulic Diameter

(mm) |

Liquid Load

(m3/m2h) |

Max. Factor m/s (Kg/m3)-1 |

|

125Y |

125 | 320 | 90 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

|

250Y |

250 | 420 | 80 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

|

350Y |

350 | 470 | 78 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

|

450Y |

450 | 520 | 72 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 500Y | 500 | 600 | 73 | 4.5 | 5-6 | 7.5 | 0.18-100 |

0.9-1.2 |

| 550Y | 550 | 650 | 74 | 5.5 | 5-6 | 6 | 0.18-100 |

1.4 |

| 700Y | 700 | 680 | 72 | 6 | 7 | 5 | 0.15-100 |

1.3 |