Silicon nitride features the best combination of mechanical, thermal and electrical properties of all advanced ceramic materials. It is especially superior to other ceramic materials on thermal shock resistance and high-temperature strength.

Silicon Nitride is currently utilized in a wide range of industries:

- Oil and Gas

- Aerospace

- Automotive

- Electronics

- Semiconductor

- Metallurgical Industry

Low Density (3.20 g/cm3) and Light Weight (1/3 weight of steel)

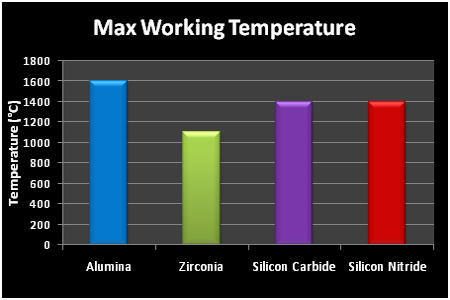

High Temperature Resistance

No melting point below 1,900 °C at ordinary atmosphere pressure.

Maximum working temperature in a neutral atmosphere: 1,600°C.

Superior Thermal Shock Resistance

With a low coefficient of thermal expansion but a high thermal conductivity, silicon nitride can experience a sudden change in the temperature rang from room-temperature to 1000°C

Excellent Oxidation Resistance and Corrosion Resistance

Doesn’t react with any inorganic acids, except hydrofluoric acid.

Able to withstand oxidation up to 1400°C

Extremely Hard and Wear Resistant

The hardest material after diamond, boron carbide, silicon carbide, giving outstanding wear resistance.

Products made from Silicon Nitride

- Bearing Roller

- Telemetry Tooling

- Valve and Sealing Part

- Welding Pin

- Nozzle

- Bearing Ball

- Metal Forming Roll

- Cutting Tool

- Substrate

- Insulation Plate/Ring

- Induction Heating Coil Support

- Turbine Blade

- Thermocouple Protection Tube

- Wear Component