Ceramic Balls

Inert Alumina Ceramic Balls

Used as catalyst cover or supporting materials in various reactors ortowers.

Features:

High mechanical strength

High resistance to corrosion (anti-acid ≥ 98%,anti-alkali≥ 95%)

Strong thermal stability and chemical stability (refractoriness ≥ 1700 °C)

Activated Alumina Ceramic Balls

Used as adsorbent, desiccant and catalyst carrier in petroleum, fertilizer and gas separation industries.

Features:

High surface-area-to-weight ratio

Strong absorption capacity(≥50%)

High mechanical strength and thermal stability

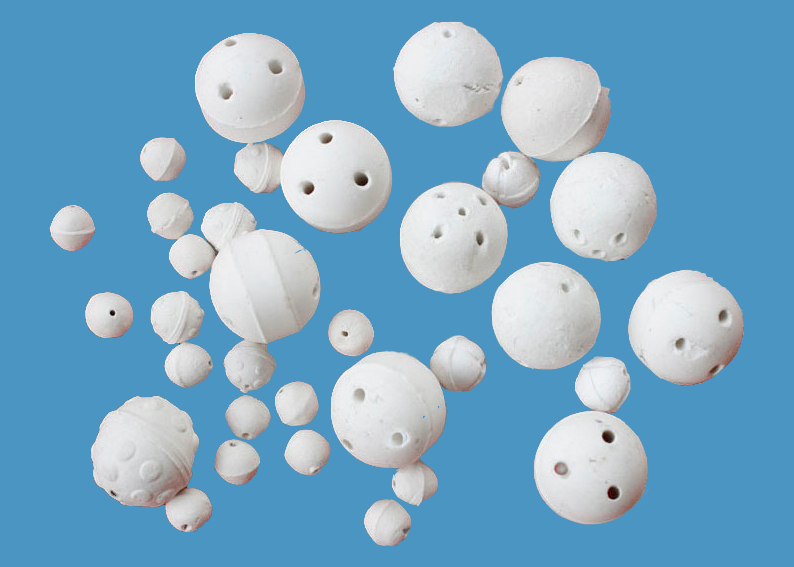

Perforated Ceramic Balls

Developed on the basis of inert ceramic ball. It increases surface area and improves porosity as well as material dispersion rate while decreasing resistance due to the perforated holes on the ball body.

Thermalstorage Balls

Used as thermal storage packing in metallurgical furnace in iron and steel industry, also used in heat accumulator for air separation

Features:

High chemical stability

Strong thermal shock resistance

Superior thermal conductivity and thermal capacity (≥1000J/kg.k)

High abrasion resistance and long service time.

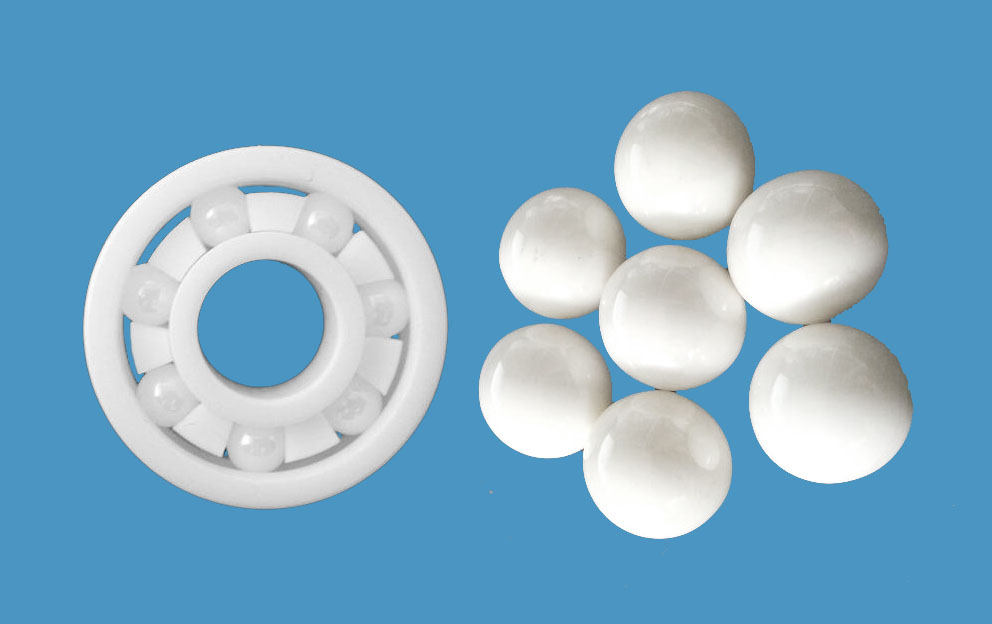

Zirconia Oxide Balls

Used as bearings in jigs, gauges, valves, high-grade bicycle parts, automotive parts, machine components, etc.

Features:

High strength and toughness(Bending strength: 800-1000 Mpa; Fracture toughness: 6-10 Mpa.M1/2; Vickers Hardness: 12-13 Gpa)

High abrasion and corrosion resistance

Low coefficient of thermal expansion

Superior load bearing capability

High grinding efficiency and long service time.

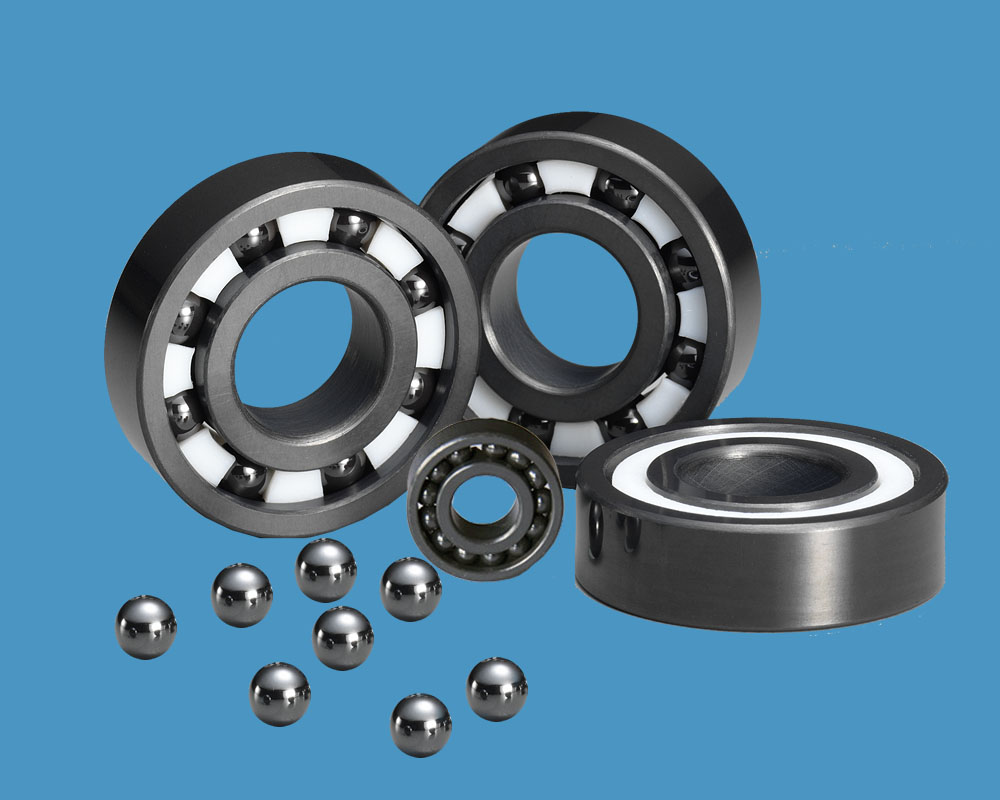

Silicon Nitride Balls

mostly used in high-endurance, very low lubrication and extreme temperature applications, such as space satellites, turbo-molecular pumps, car engine parts, hybrid bearings and metal working, etc.

Features:

Excellent corrosion resistance

Lower Thermal Expansion

Lightweight

high fracture toughness and high strength

Superior Surface Finish